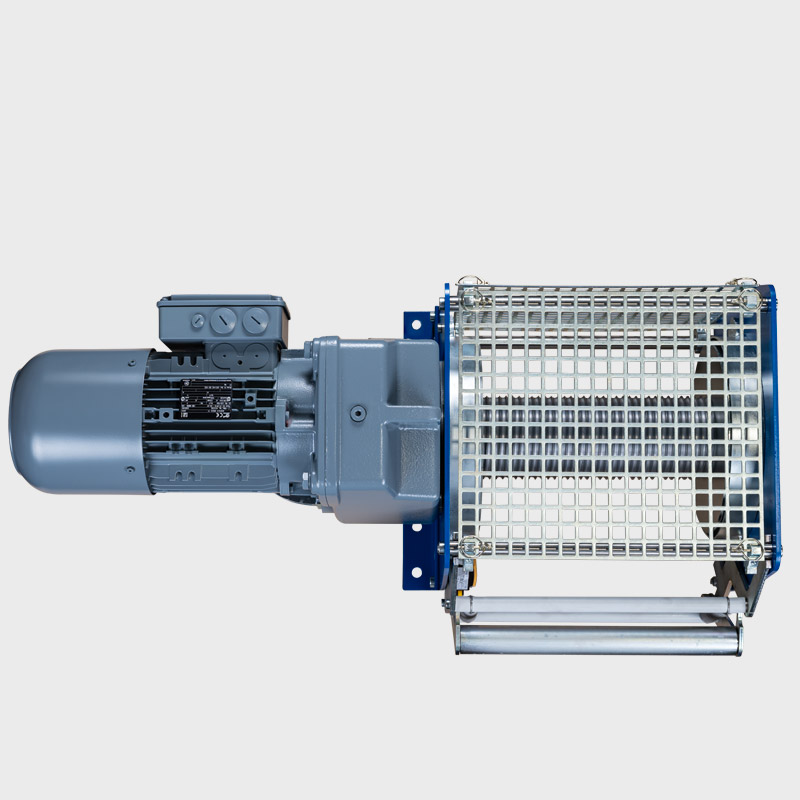

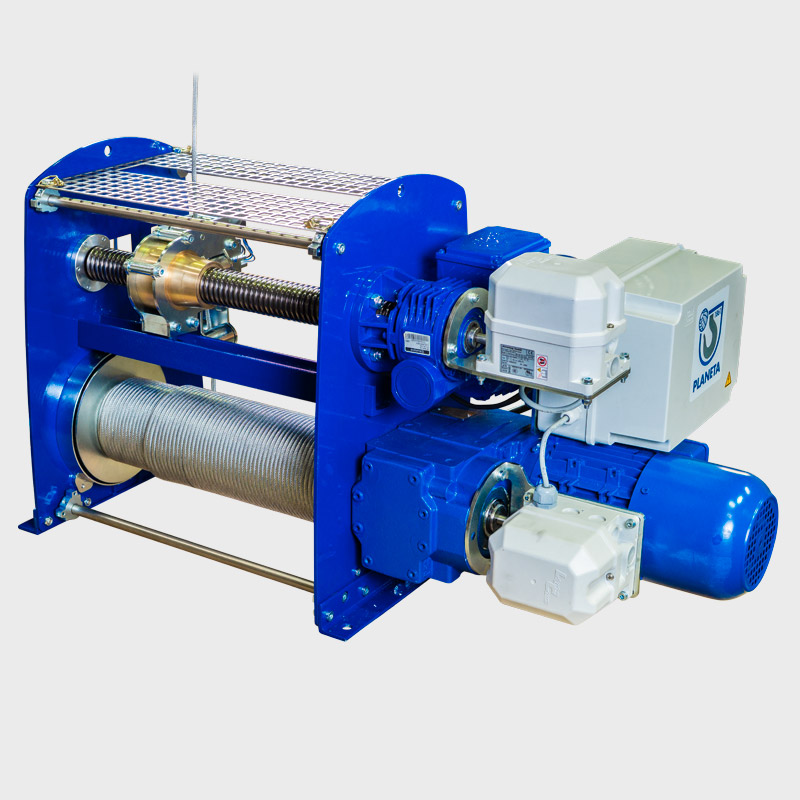

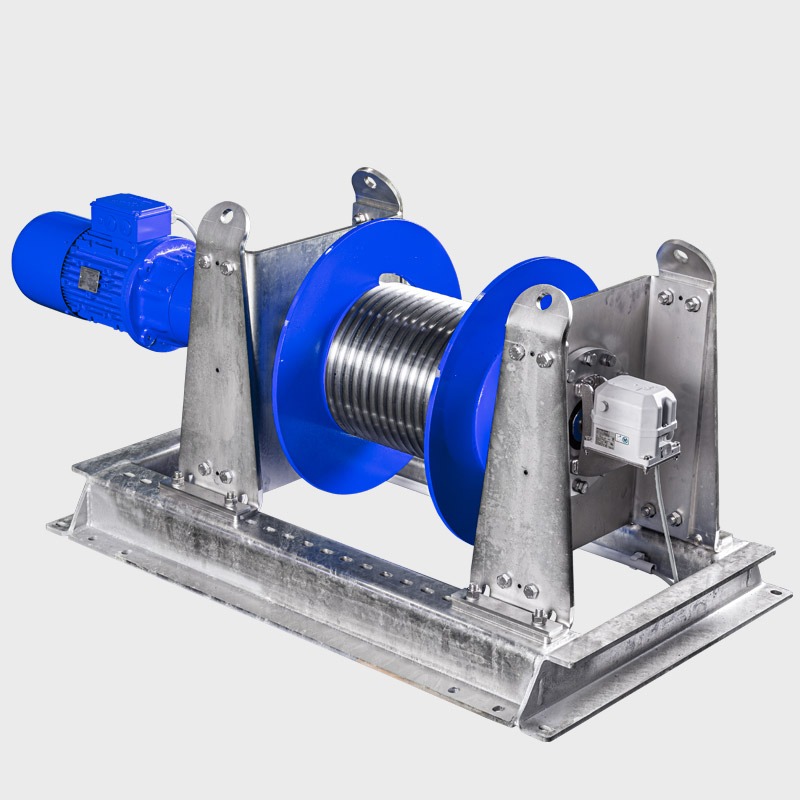

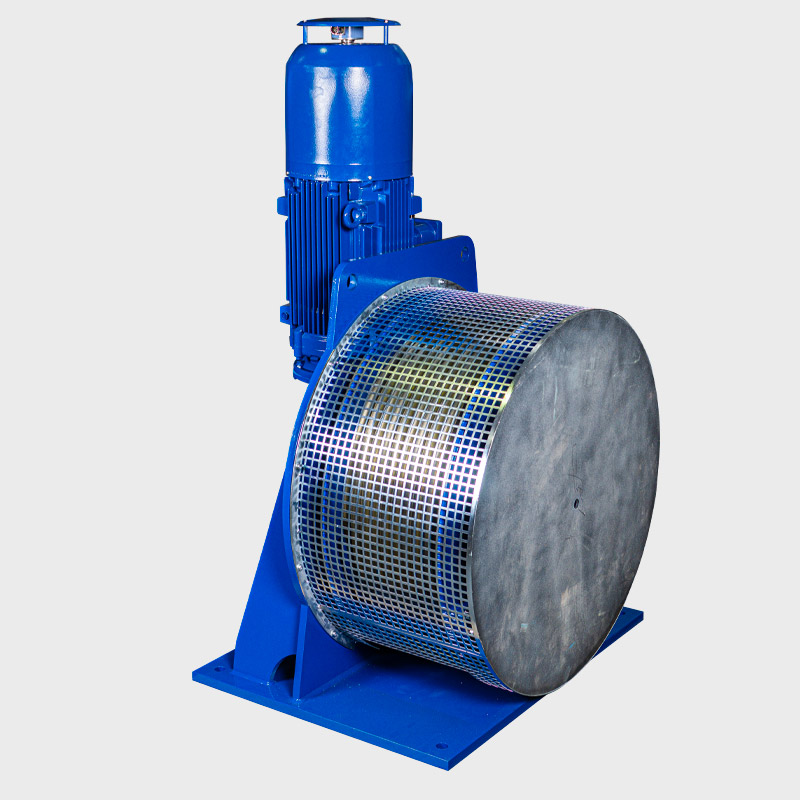

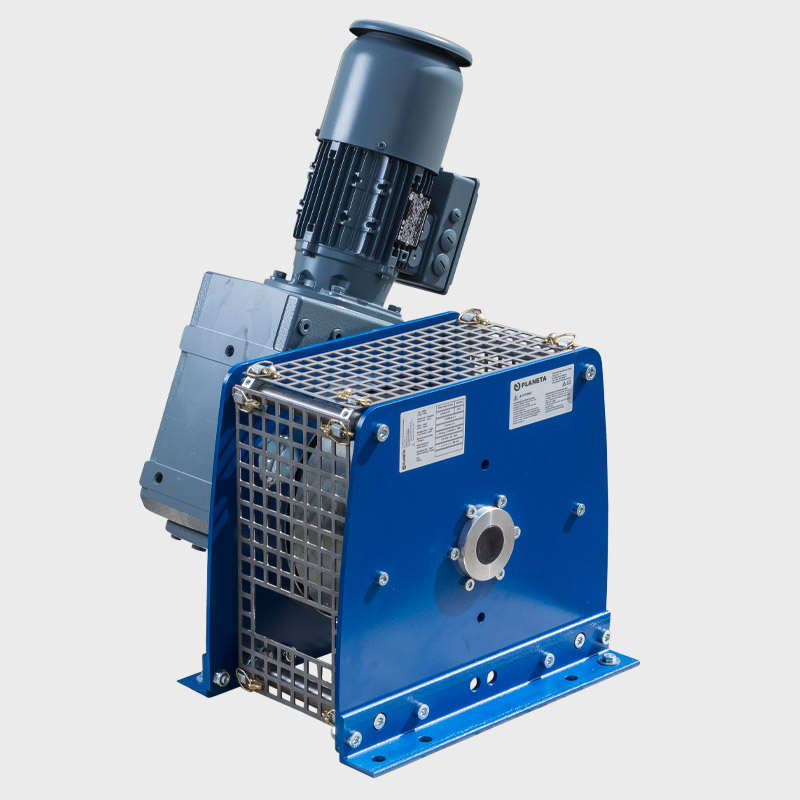

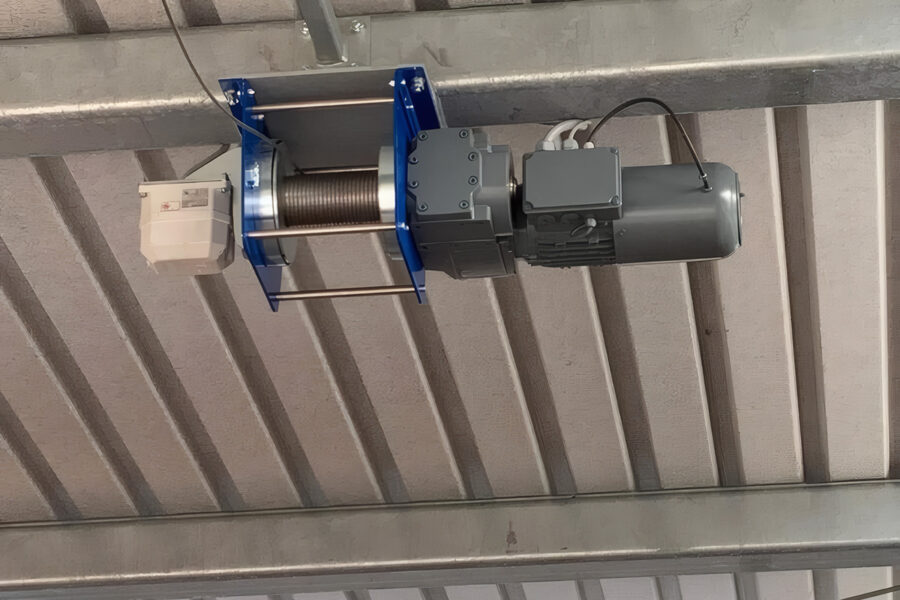

Electric rope winch PFW-E

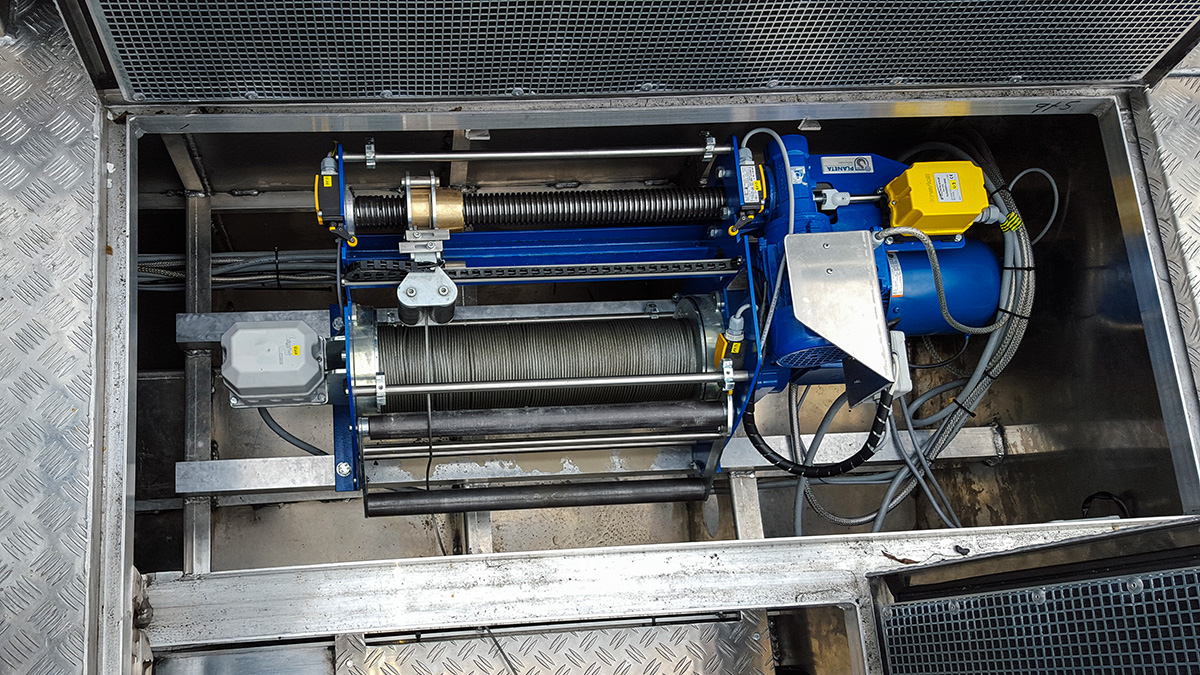

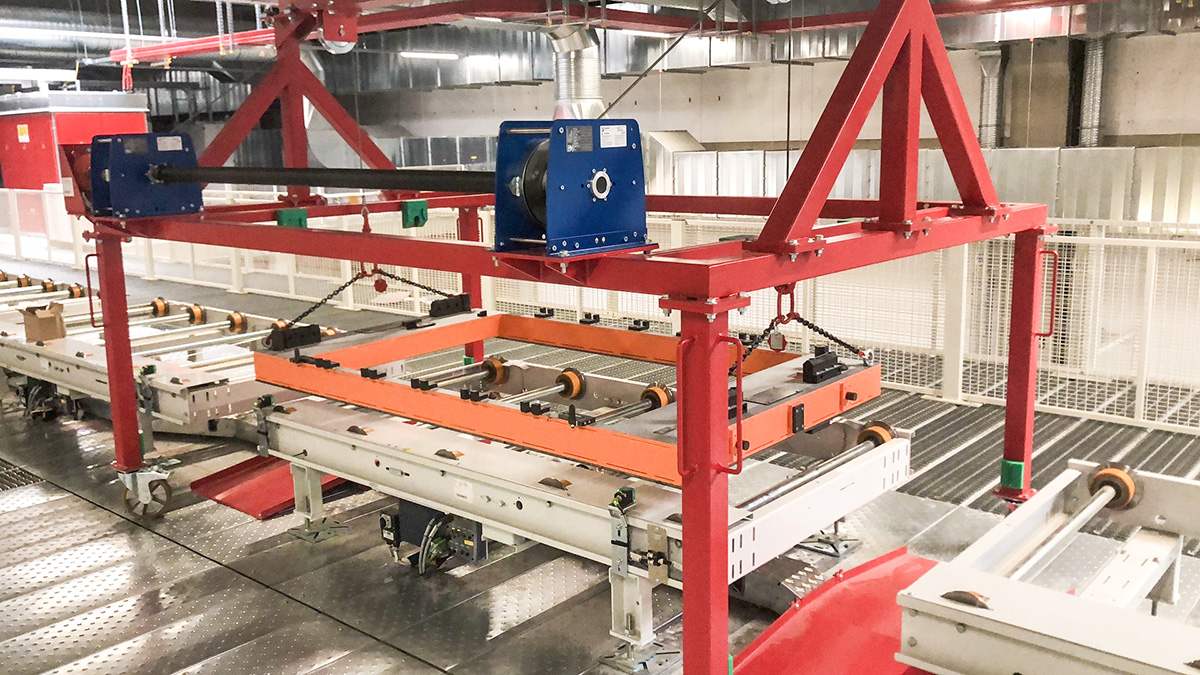

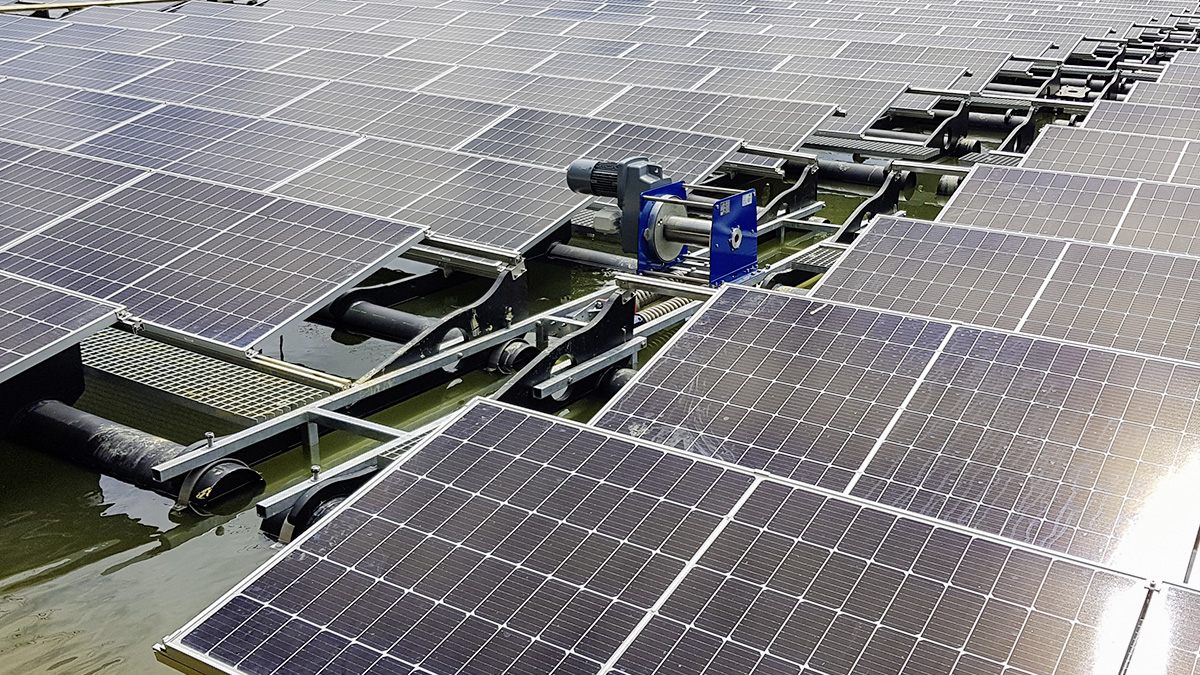

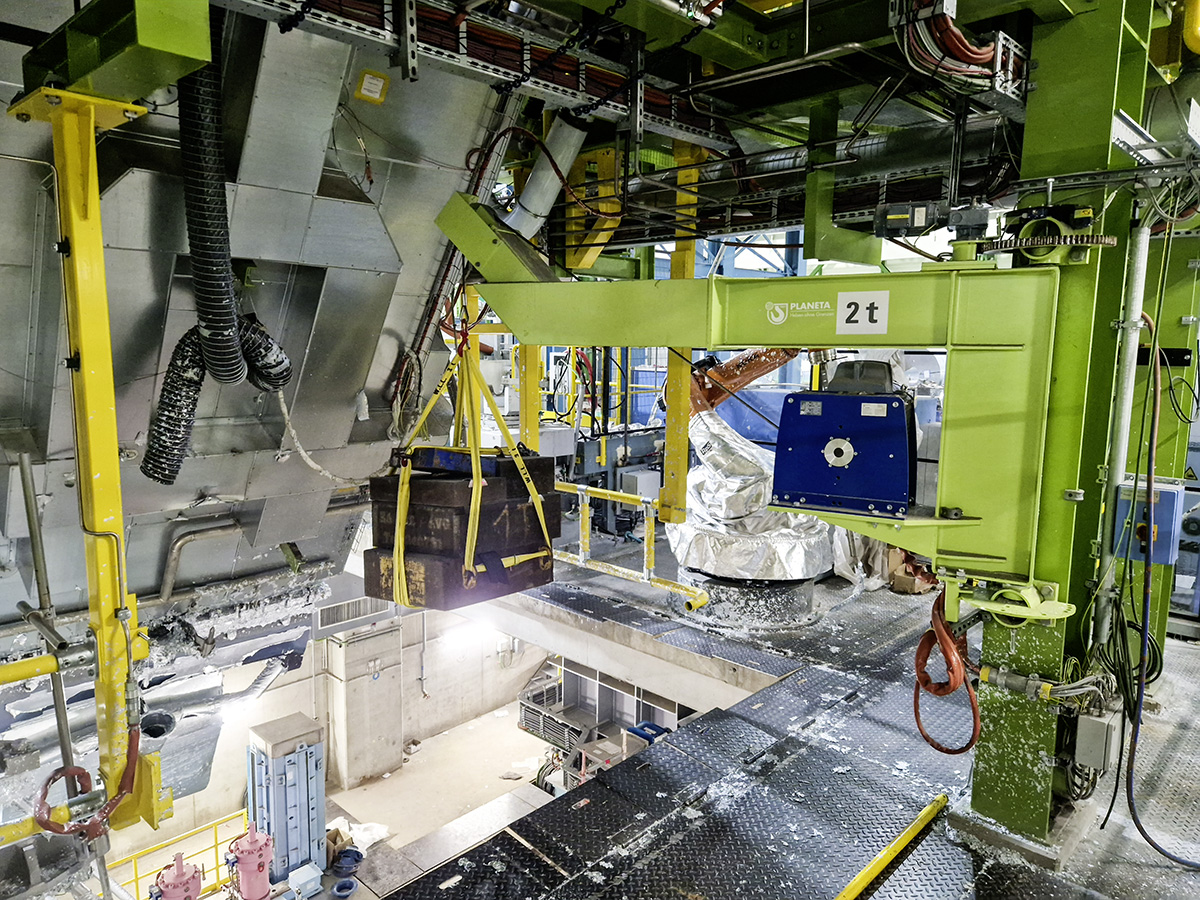

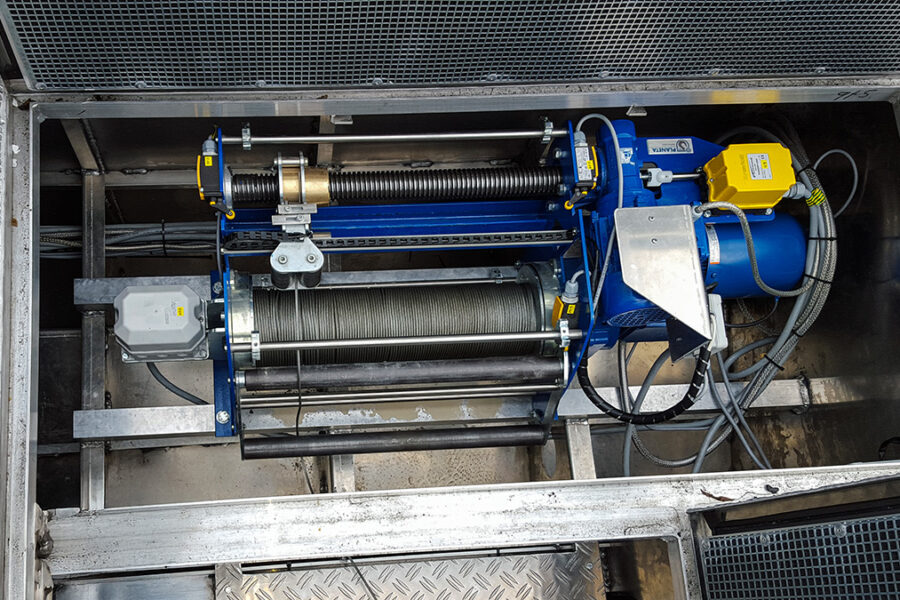

As a lightweight industrial rope winch, the PFW-E electric rope winch is the entry-level model for customized PLANETA solutions for pulling, lifting and positioning loads of up to 3,000 kg. With two different drum diameters, a modular design and a range of equipment included, it can be adapted to suit any conditions, even at a later date. Because many parts are kept in stock, the production time of the PFW-E electric rope winch is very short, even in special versions.

Drive

The spur gear is equipped with a three-phase brake motor as standard. The standard operating voltage is 3 phase / 400 V / 50 Hz. The duty cycle is in the case of 60 % and thus enables almost uninterrupted use under the most difficult conditions. For unprotected outdoor use of the electric rope winch, the brake motor complies with protection class IP55. Other operating voltages, alternative drive types and higher duty cycles and degrees of protection are available on request.

End position switch-off

The limit switch is installed on the drive side as standard to save space. On request, or in the case of using the manual freewheel clutch, it can be mounted on the opposite side, above the drum bearing. In addition to the standard version as an emergency limit switch, we offer the limit switch optionally with 4 contacts as an operational limit switch to ensure that the emergency limit switch is not actuated during operation, as required by the Machinery Directive. For use with the PFW electric rope winch, for example in combination with a frequency converter control system, the limit switch can be equipped with an integrated incremental encoder at the factory. The IP 65 protection class and the high-quality workmanship of the limit switch make it possible to use the rope winch in almost any environment.

the rope drum

In the basic version, we supply your PFW electric rope winch with a smooth drum base. On request, we can provide the rope drum with a groove to achieve a longer rope service life and smoother running of the rope. You can choose between two drum diameters. The standard diameter is based on a D/d ratio of 14 and therefore meets the requirements of drive group 1Bm. The double drum diameter is available for single-layer applications of the highest precision. Because of the modular design of the rope drum, your PFW rope winch drum can even be converted from smooth to grooved in the case of retrofitting at our factory. Special versions with multiple rope outlets, drum separators or stainless steel versions are available on request!

Base frame

Torsion-resistant yet flexible, it adapts to almost any surface. Many accessories are retrofitted and can therefore be modified during use. We install side guards as standard, which effectively prevent the cable from jumping off. In addition to being able to run the rope in almost any direction from the rope winch drum, the stainless steel frame bars are used for easy handling during transportation or assembly.

Options

For the first time, it is possible to retrofit or modify many of the options because of the modular design. First and foremost is the manual freewheel clutch, which decouples the rope drum from the drive and brake to allow the rope to be pulled off quickly.

Simply choose from our catalog of options:

- Grooved drum

- Special drum length

- Limit switch

- Rope pressure roller

- Slack rope switch

- Drum protection covers

- two or more rope exits

- Handbrake release

- Emergency hand crank

- Various protective coating systems

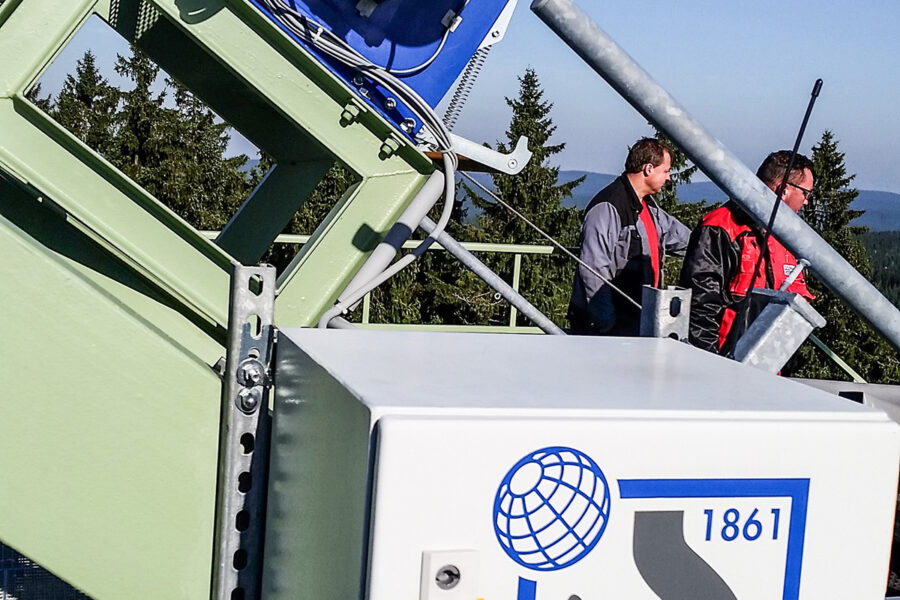

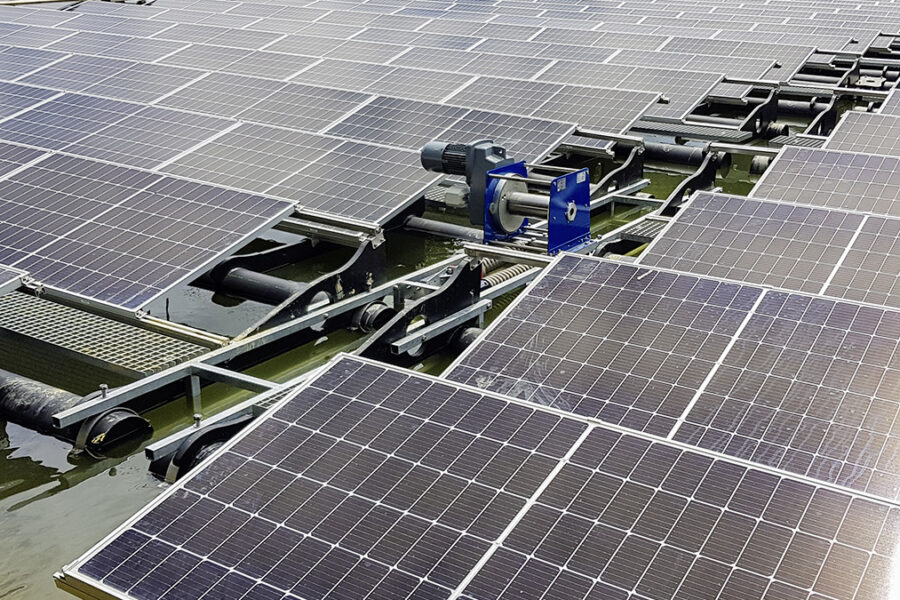

With our C5 paint finish in accordance with ISO 12944, the PFW electric rope winch in combination with an increased protection class for the motor and stainless steel connecting elements in the offshore version can also be used in salt water sea air environments or on ships. Moving special solutions are always possible on request. The limit switch is installed on the drive side of the rope winch as standard. On request, or in the case of using the manual freewheel clutch, it can be mounted on the opposite side, above the drum bearing.

Executions

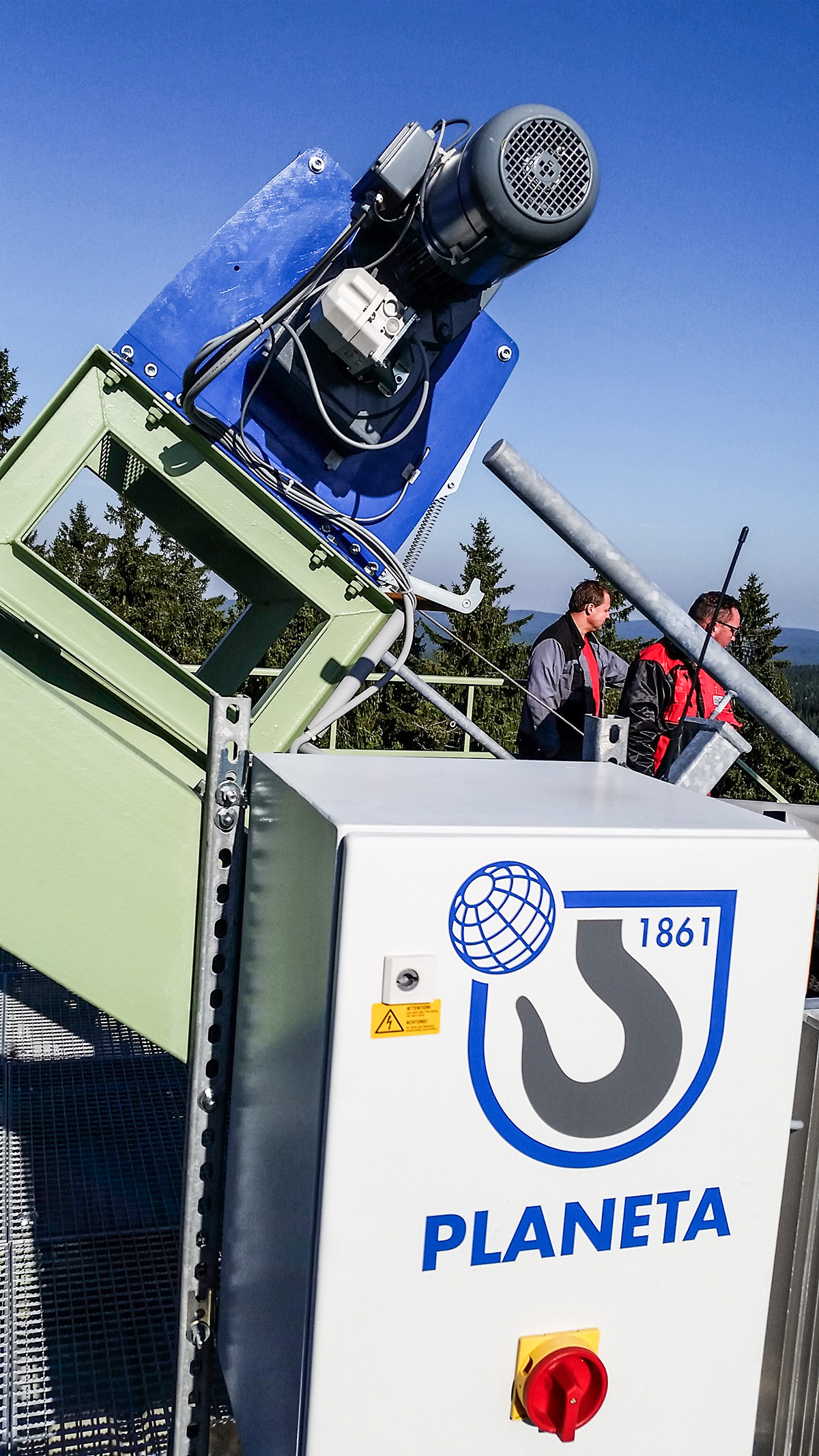

The rope winch can also be suitably equipped for explosion-protected areas, as well as for theaters, stages and studios (DGUV V17) where people may be under the moving load. Special designs such as two- or multi-part applications and traversing winches are also available from the standard range.

Made in Germany

The PFW electric wire rope winch series combines a modern design, innovative technology and outstanding components that are produced exclusively in Germany. Each winch is dynamically tested at 125% of the rated load before delivery and leaves our factory with a 24-month guarantee.

Downloads

Specifications

- Capacities from 250 kg to 3,000 kg

- Spur gearbox and brake motor

- AC or three-phase motor

- Different speeds and rope capacities

- Protection class IP55 – 66, duty cycle 60 % – 100 %

- Low maintenance due to lifetime lubrication

- Engine group M3 (1Bm)

- Documentation optionally in German or English

- Test logbook and EC declaration of incorporation

Options

- Rope and hook fully assembled, several rope exits

- Grooved and extended drum, freewheel clutch

- Drum protection cover and special paintwork

- Versions for ATEX and stages/studios

Training

10.03.2026 | Live

Registration for the course:

Product training for manual lifting equipment

13.04.2026 | Online

Registration for the course:

Product training for manual lifting equipment

|

Registration for the course:

Product training for manual lifting equipment

|

Registration for the course:

Product training for manual lifting equipment

|

Registration for the course:

Product training for manual lifting equipment

|

Registration for the course:

Product training for manual lifting equipment

Product inquiry

Do you have any questions about our products? Then contact us or arrange a non-binding consultation.

Start product inquiry

Construction & modification

Do you have special requirements for your lifting technology or cable winch product? With us, you always have the option of modifying existing products or having them designed completely tailored to your needs.

Start design request

Error: Contact form not found.

CERTIFIED QUALITY

Standardized processes and the highest quality standards are the cornerstones of our claim and self-image – and have been for over 150 years.

Certifications

Memberships

What’s your challenge?

We believe that challenges are there to be solved. What can we do for you?

Request products

Do you have any questions about our products? Then contact us or arrange a non-binding consultation.

Start product inquiry

Request industrial service

Whether initial consultation, feasibility studies, individual product development, training, aftersales or maintenance and repair inquiries – we are there for you.

Start service request

Order newsletter

Lifting technology that inspires. In our newsletter, we show you in exciting stories and use cases what good lifting technology can really achieve.

Subscribe to the newsletter

Order catalog

We have listed a wide range of products for you in our PLANETA catalogs. We are happy to provide you with our catalogs digitally or by post. You can find an overview of all catalogs for download here.

Start catalog order