Maximum power

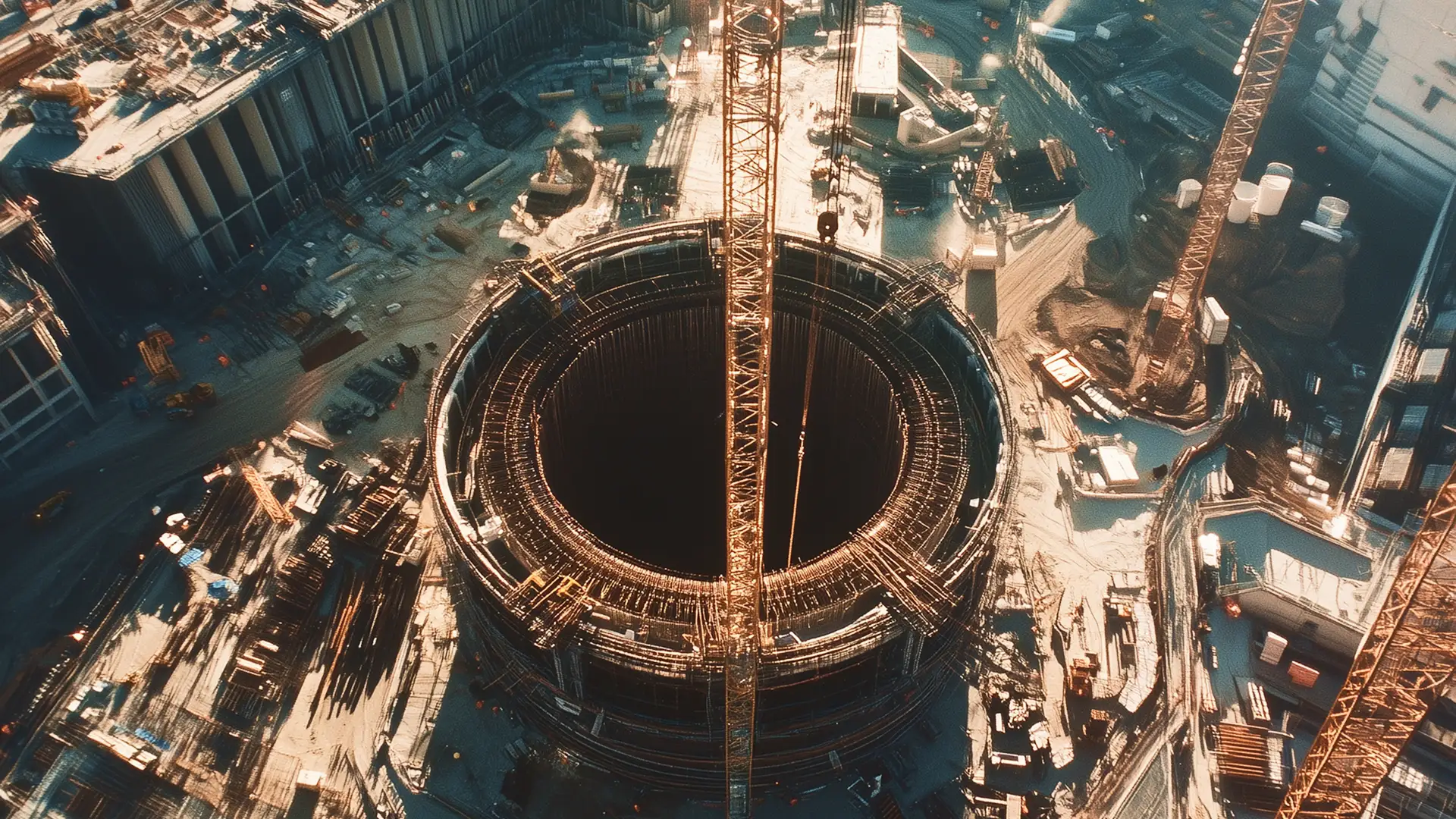

The HPC-2 project uses the world’s largest crane, “Big Carl”, which can lift up to 5,000 tons. With 12 motors and a height of 250 meters, this crane plays a central role in the construction of the reactors.

Table of contents

As part of the Hinkley Point C (HPC-2) project, an ultra-modern nuclear power plant in the south of England, PLANETA hoisting technology was faced with the challenge of equipping the polar cranes of the reactor domes with extremely robust and durable winch systems. The requirements were clear: the highest safety and durability standards had to be met because there must be reliable operation of the winches over a period of 60 years. Because we worked closely with the customer, we were not only able to develop innovative solutions, but also lay the foundations for a long-term partnership.

The polar cranes in the reactor domes of HPC-2 are essential for the safe operation of the plant. In order to meet the high safety requirements, the winches had to have special functions such as an emergency lowering option and a mechanical speed limiter. In addition, an extremely long service life of up to 60 years, including the availability of spare parts, was required. Meeting all these requirements under extreme environmental conditions such as radiation and corrosion posed a particular challenge.

PLANETA developed customized electric rope winches that are specially tailored to the requirements of HPC-2. To ensure durability, the winches were made from high-quality steel and special alloys that can withstand extreme conditions. A multi-layer anti-corrosion coating was applied to protect the winches against environmental influences. Because of simulations and tests, we were able to ensure that our winches function optimally even under the demanding conditions in the reactor domes.

For the HPC-2 project, we used electric rope winches that are characterized by their robustness and precise control. They have an emergency lowering function that enables the load to be lowered immediately in an emergency, as well as a mechanical speed limiter for maximum operational safety. The winches have been specially developed to meet the high requirements for reliability and durability.

An essential part of our offer was the development of a comprehensive maintenance concept that optimizes the service life of the winches. PLANETA not only provides regular inspections and spare parts, but also on-site training for the technical staff to ensure that the winches remain in optimum condition at all times. Our after-sales service ensures that the HPC-2 project can be operated safely and reliably for decades to come.

The successful implementation of the project led to HPC-2 gaining further confidence in PLANETA’s solutions. As a result, a second set of winches was reordered and we are now also in the pipeline as the preferred supplier for the next reactors. Thanks to our reliable products and comprehensive service, PLANETA has been able to build a long-term partnership with HPC-2.

PLANETA was once again able to demonstrate its expertise in the development of durable and safe lifting technology in the HPC-2 project. With our customized electric rope winches, we not only met the customer’s requirements, we exceeded them. Thanks to our collaborative approach and innovative solutions, we have been able to secure a long-term partnership with HPC-2. Contact us today for a no-obligation consultation and find out how you too can benefit from our customized lifting solutions.

We support you in finding the right products and solutions for your project. Please contact us – we will take the time to answer your questions and advise you individually.

We believe that challenges are there to be solved. What can we do for you?

Do you have any questions about our products? Then contact us or arrange a non-binding consultation.

Whether initial consultation, feasibility studies, individual product development, training, aftersales or maintenance and repair inquiries – we are there for you.

Lifting technology that inspires. In our newsletter, we show you in exciting stories and use cases what good lifting technology can really achieve.

We have listed a wide range of products for you in our PLANETA catalogs. We are happy to provide you with our catalogs digitally or by post. You can find an overview of all catalogs for download here.