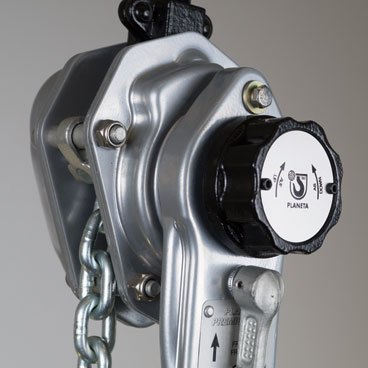

Wir fertigen Qualitäts-Hebezeuge die auf Langlebigkeit ausgelegt und für die härtesten Einsatzbedingungen konzipiert sind. PLANETA-Flaschenzüge, Hebelzüge, Fahrwerke, Kombifahrwerke, Drucklufthebezeuge und Elektrokettenzüge verrichten auf der ganzen Welt zuverlässig ihren Dienst.

PLANETA bietet eine Vielzahl von explosionsgeschützten Hebezeuge, die nach der neuesten ATEX-Herstellerrichtlinie 2014/34/EU ausgelegt sind.

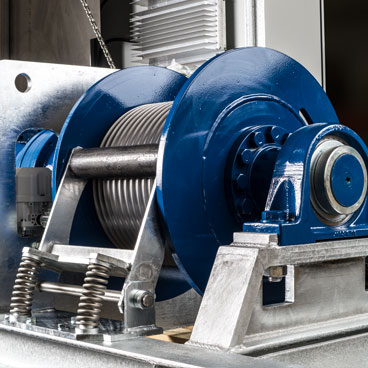

Qualitäts-Seilwinden Made in Germany. PLANETA fertigt individuelle Industrie-Seilwinden für die unterschiedlichsten Branchen (z.B. Anlagenbau, Schifffahrt, Windkraftanlagen). Folgende Antriebsarten hat PLANETA im Programm: manuelle Handseilwinden, Elektroseilwinden, Druckluftseilwinden und Hydraulikseilwinden.

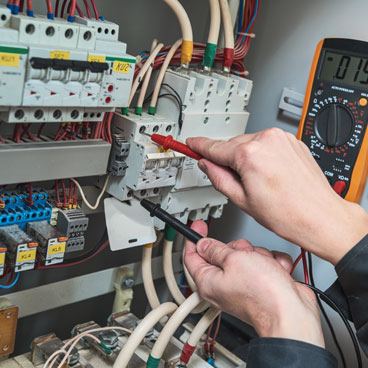

Sie suchen einen zuverlässigen Partner der Ihre Hebetechnik in Windkraftanlagen und Industrie nach DGUV-Vorschriften regelmäßig prüft und wartet? Brauchen Sie Beratung und Hilfe bei der Umsetzung bei der Modernisierung Ihrer Krananlagen? Dann sind Sie beim PLANETA-Service genau richtig.

Lernen Sie die Vorzüge unserer Hebezeuge kennen. Wir machen sie fit bei der richtigen Anwendung der Hebezeuge und liefern Ihnen gute Verkaufsargumente. Für Handhebezeuge, Fahrwerke, Elektrokettenzüge und Seilwinden bieten wir regelmäßig Termine für Online-Produktschulungen via TEAMS an.

PLANETA-Seminare geben Ihnen die Grundlage die jährlich vorgeschriebene Prüfung nach DGUV52 & 54 sowie BetrSichV rechtssicher und selbstständig durchzuführen. Erfahrene, von der BG ermächtigte Kransachverständige vermitteln Ihnen die erforderlichen Prüfschritte und geben Ihnen einen Leitfaden durch die vielfältigen Vorschriften und Regelwerke zur Arbeitssicherheit.

NEUE Schulungstermine:

NEUE Schulungstermine: NEUE Schulungstermine:

NEUE Schulungstermine: