PLANETA winches and FYBERHOIST: Safe hoists for sensitive industries

In industries where maximum cleanliness and precision are required, conventional hoists often reach their limits. PLANETA offers tailor-made solutions for cleanrooms and food processing companies with its hoist winches and the FYBERHOIST. Find out how our innovative hoists with textile belts and UHMWPE fibers increase occupational safety and meet the highest cleanliness standards.

Maximum precision and purity with modern lifting equipment

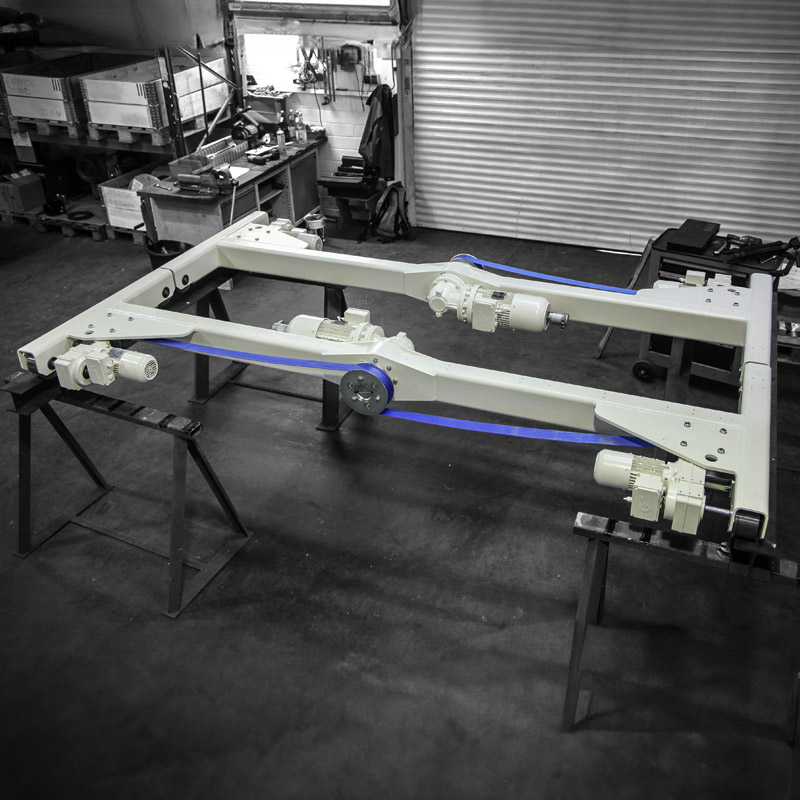

In critical applications, the use of steel cables can pose risks to occupational safety and disrupt operations. PLANETA-Hebetechnik offers a tailor-made solution: hoist winches that use textile straps as a load-bearing medium and therefore represent a safe alternative for special applications. Particularly noteworthy is the PLANETA FYBERHOIST, which has been specially developed for clean rooms and food processing plants and is in compliance with the highest industrial standards.

Belt winches: The clean alternative to steel cables

Tape winches from PLANETA open up new possibilities in applications in the case of which the use of steel cables is problematic. Because they use high-strength textile tapes, our winches offer a risk-free and flexible solution for many lifting applications. These belts are also ideal for sensitive environments where cleanliness is a top priority. Companies in the food processing, pharmaceutical, medical and semiconductor industries benefit from this innovative lifting solution.

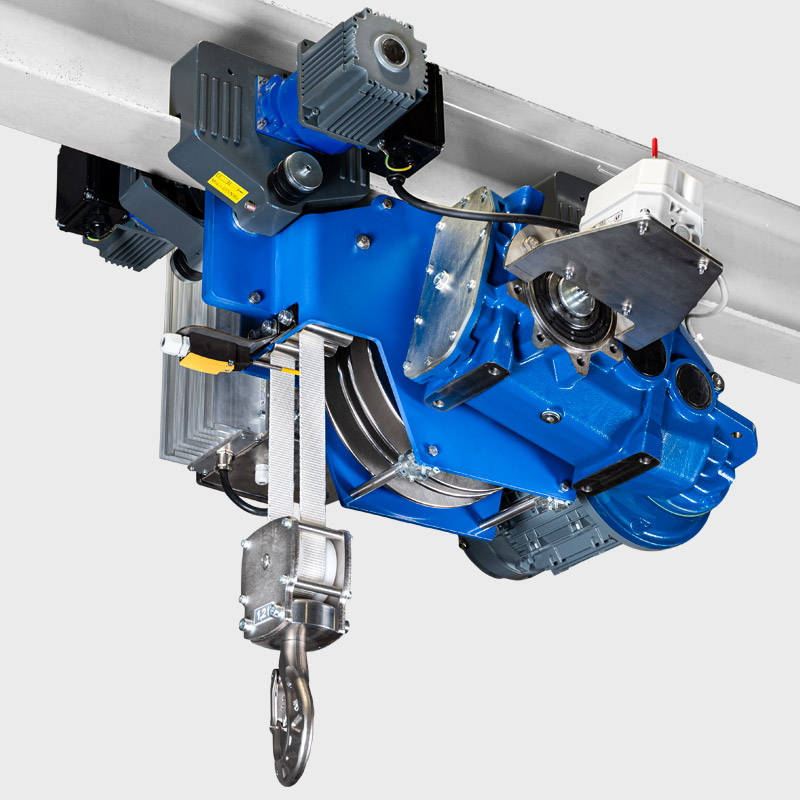

FYBERHOIST: Specially developed for cleanrooms and food processing companies

The PLANETA FYBERHOIST is a specially designed belt hoist for clean rooms and food processing plants. In production environments where the highest levels of cleanliness are required, conventional electric hoists cannot be used due to particle contamination. Our engineers have studied the requirements of these industries in detail and used state-of-the-art technology to develop a hoist that uses UHMWPE ropes and belts. These ultra-strong fibres enable dust-free and clean lifting, minimizing contamination.

Benefits of UHMWPE fibers

The UHMWPE fibers used in the FYBERHOIST offer numerous benefits. Not only are they extremely robust and durable, they are also easy to clean, which is crucial in cleanrooms. They also ensure smooth, quiet and safe lifting without the risk of material abrasion or particle contamination. This ensures high product quality and significantly increases the safety of the working environment.

Electronic controls and safety devices

The PLANETA FYBERHOIST also impresses with its sophisticated electronic controls, which enable vibration-free and shock-free handling of even the heaviest loads. Redundant safety devices ensure that operators in the safeguarded areas are protected from overloading and dangerous working outside the specified limits. These innovative functions make the FYBERHOIST the ideal solution for cleanroom applications.

Standards and certifications

The FYBERHOIST complies with both the Chinese standard GB50073-2001 and the European standard ISO14644-1. These certifications prove the high quality and reliability of our lifting technology solutions. PLANETA focuses on quality and safety in order to meet the demanding requirements of our customers.

Lifting technology for the future

With PLANETA’s belt winches and the FYBERHOIST, you can rely on state-of-the-art lifting technology. Our solutions not only offer maximum safety and cleanliness, but also flexibility and user-friendliness. This is guaranteed by our continuous innovations and our commitment to your needs.

Service and support

PLANETA not only supports you with high-quality products, but also with first-class service. Our experts offer comprehensive advice, training and technical support. We accompany you from the selection of the right lifting technology to installation and regular maintenance. Rely on our service to maximize the safety and efficiency of your lifting equipment.